Abschnitt 2 - 2 Definitions

The terms below are defined as follows for the purpose of the present DGUV Rule:

2.1

Vessels and confined spaces are areas constrained completely or predominantly by rigid walls and in which, owing

to their physical confines, inadequate air replacement rates, or the substances, mixtures,

contaminants or equipment found within them or introduced into them, particular hazards

exist or may arise that substantially exceed the normal prevailing hazard potential

of workplaces. Areas only partly surrounded by rigid walls in which however, owing

to the design of the areas or to the site conditions, hazardous substances may accumulate

or an oxygen deficit may arise, also constitute confined spaces in the sense of this

DGUV Rule.

Where the incidence of particular hazards (see below) cannot reliably be ruled out, areas such as the following must also be regarded as confined spaces:

Tank pits

Pits in general

Shafts

Sewers

Ships’ holds

Weighbridge pits

Cavities in building structures and machines

Box girders of bridges and cranes

Hubs, rotor blades and spinners of wind power installations

Particular hazards caused by substances or mixtures may exist or arise in confined spaces and vessels as a result of:

Work methods such as welding, grinding, cleaning with liquid or solid substances

Surface treatment work

Agitation of residues

Biological processes, such as fermentation, putrefaction

Chemical reactions

Gases used for purging

Substances and mixtures entering through leaky lining or valves

Oxygen deficit; this may be caused by inert gases used for purging, or by substances (including the material from which the vessel is manufactured) that absorb the oxygen, bind it chemically or physically or displace it (see also Annex 5); the consumption of oxygen or unsuitable and inadequate ventilation during work in vessels, silos or confined spaces may also lead to an oxygen deficit.

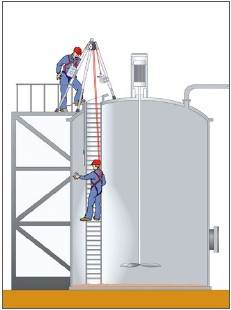

Fig. 1

Maintenance work

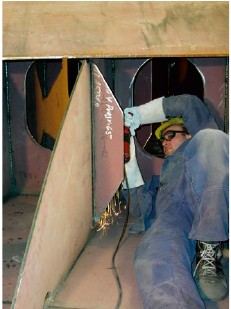

Fig. 2

Repair work

Fig. 3

Inspection tasks (leaning into the vessel or confined space): permissible only with

additional protective measures. In this case: a protective mesh in the manhole that

prevents persons from falling into it

Fig. 4

Cleaning tasks

Enrichment with oxygen, for example owing to operator error or leaks arising during welding work

Hot substances or mixtures, bulk materials, liquids or other fluid substances and mixtures present in or entering vessels or confined spaces

Removal of caked deposits

Gases, vapours, mists or dusts which may arise as a result of fire or explosion

Equipment present in vessels, silos and confined spaces may for example present or give rise to particular hazards such as:

Moving parts or installed equipment such as mixing, crushing, decompaction, conveying or ventilation equipment

Heated or cooled parts of vessels and installed equipment

Closing or opening fittings in pipes, e.g. gate or butterfly valves, explosion decoupling equipment

Fig. 5

Sewer

Fig. 6

Pit

Electrical equipment that is live under operational conditions, such as resistance and HF heaters

Electrical equipment such as hand lamps, electric tools, electric welding equipment

Radiation, caused for example by instruments

Cleaning equipment, e.g. high-pressure cleaners

Particular risks of mental stress may be presented for example by:

Confined spaces

Working at a height, e.g. in silos or shafts

Limited visibility, poor communication with the outside world/with the safety person

Fig. 7

Vessel during production

Fig. 8

Shell ring below a column

Particular hazards may also be presented for example by:

Fixed installations such as baffle plates, column bases, raised floors

Difficulty of access and rescue owing to the space constraints

Auxiliary equipment such as ladders or scaffolds

| The classification of a location as a "confined space" should not be based solely upon its dimensions, but should also always take account of the particular hazards presented by it. In normal use, broom cupboards or bank vaults for example do not constitute confined spaces in the sense of this DGUV Rule. |

|---|

2.2

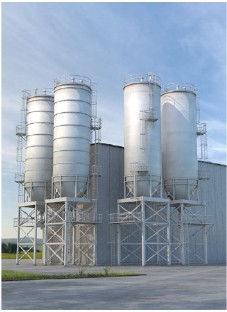

Silos are building structures for the storage of bulk materials. They are filled from the

top and emptied from the bottom or side.

The term bunker is commonly used in some areas of industry. For particular hazards, refer to the definition of "Vessels and confined spaces".

2.3

Work in this context covers tasks performed by persons in vessels, silos and confined

spaces.

Such work includes:

Maintenance work, such as:

Repair or replacement

Servicing, rust-proofing, lubrication or adjustment

Inspection work

Cleaning work, including the removal of residues

Modification work

Tasks performed during manufacturing processes

Fault clearance

Fireproofing

Access includes:

Non-assisted access

Assisted access

Leaning in

Fig. 9

Silo

Fig. 10

Sewer access opening

2.4

Access techniques are work methods that permit access to the vessel, silo or confined space (generally

with the assistance of work equipment). Examples of such methods are:

Access simply by climbing in, without the use of equipment (this is generally the case with access points located at the bottom)

Access by means of ladders (permanently installed or mobile ladders)

Access by means of suspended access equipment in accordance with DGUV Rule 101-005

Access by means of a full body harness serving as a lifting and holding device, together with a winch for the transport of persons

Fig. 11

Manhole

2.5

Work positioning techniques in the sense of this DGUV Rule are work methods in which persons are positioned at a certain point in the vessel, silo or confined space in order to perform work in the sense of No 3. The persons remain in the access equipment for the duration of this work. For the purpose of work positioning, suspended access equipment forming the scope of DGUV Rule 101-005 or rope access and work positioning techniques in accordance with TRBS 2121 Teil 3 and DGUV Informative publication 212-001 governing work performed with the use of such techniques can be used.

2.6

Access openings to vessels and confined spaces include but are not limited to:

Doors

Hatches

Manholes

Ladders

Manhole steps

Fig. 12

Manhole (unfavourable position, conditions unfavourable to rescue)

Fig. 13

Permanent ladder

2.7

Clearance measurement in the sense used in this rule is the measurement of a possible concentration of

a hazardous substance or of the oxygen concentration in order to determine whether

the atmosphere in the vessel, silo or confined space can be cleared for safe working.

Clearance measurement is not synonymous with measurement in the sense of the German Ordinance on hazardous substances or TRGS 402, "Identification and assessment of the risks from activities involving hazardous substances: inhalation exposure".

2.8

Continual monitoring of the concentrations of oxygen or hazardous substances during work has the purpose

of determining that the atmosphere in the vessel, silo or confined space continues

to permit safe working after the clearance measurement has been performed.

2.9

The chief supervisor is a person tasked by the employer with supervising the preparations for and performance

of work in vessels, silos and confined spaces.

Refer to Section 8 (1) of DGUV Regulation 1, "Principles of prevention".

2.10

The safety person is a person who maintains continual contact with the persons working in the vessel,

silo or confined space and who takes or initiates rescue measures if necessary.

2.11

An oxygen deficit is defined in this context as a state in which the oxygen concentration is lower

than that of the natural breathing air, i.e. < 20.9%.

2.12

Excess oxygen is defined in this context as a state in which the oxygen concentration is greater

than that of the natural breathing air, i.e. > 20.9%.