Abschnitt 2 - 2 Information for the design of hand-operated cutting devices

General

Safety devices must be sufficiently strong to sustain the stresses to be expected and be so designed as to allow the cutting area to be observed.

Surfaces and edges must be designed in such a way that they cannot cause injuries.

Racks for holding the cutting devices and paper dispensers must be designed and installed in such a way that they can safely support the loads when used as intended. Their stability and load-bearing capacity must be adequate for the operational stresses and must be verified by the manufacturer by means of mathematical load-bearing capacity verifications for the load-bearing elements or by load tests.

The maximum admissible loads must be indicated on the rack.

Cutting devices must be secured against slipping. This can be achieved, for example, by providing rubber knobs on the underside of the cutting device.

Cardboard shear cutters, manual guillotine trimmers

The knife must be held in its top position by positive action, for example by springs, friction or counterweight.

Counterweights are required to be positively secured.

Friction elements for positively holding the knife must be adjustable.

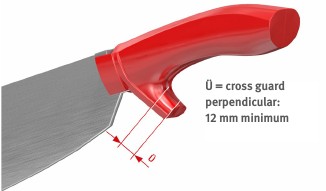

On the bottom side, the knife handle must be provided with a cross guard perpendicular to the spine of the knife in order to prevent fingers sliding onto the blade. This guard must have a length of 12 mm minimum (see figure 6).

Cross guards are not required where the distance between the cutting edge and the handle is at least 70 mm or where blunt knives in accordance with figure 9 are used.

The knife edge must be secured in every position.

The distance between the guard and the blade plane must be as small as possible. For cutting lengths up to 590 mm, the distance must not be greater than 3 mm and for cutting lengths of more than 590 mm, the distance must not be greater than 6 mm.

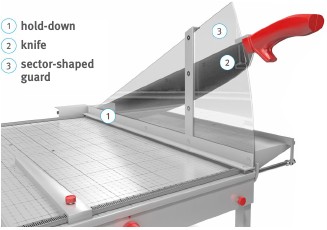

The knife edge is secured, for example, by a sector-shaped guard behind the blade plane up to the hold-down (Fig. 7). The sector-shaped guard must not have any openings and no recesses on the cutting side

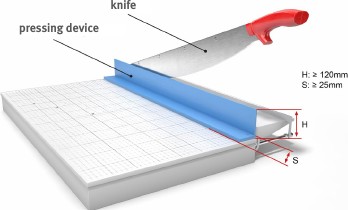

Cutters with a cutting length of more than 1.3 m can do without the sector-shaped guard if they are provided with a pressing device (hold-down) which has a height of at least 120 mm and its upper edge is at a distance o 25 mm minimum from the cutting plane (Fig. 8).

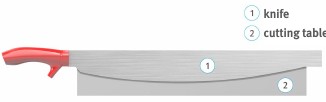

Fig. 6

Knife handle

Fig. 7

Guillotine trimmer

Fig. 8

Pressing device

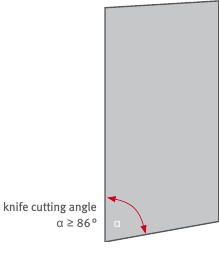

A safety device (e.g. a sector-shaped guard) can be omitted if the knife angle is more than 86 ° (blunt knife edge) and the thickness of the knife edge is at least 1.5 mm (Fig. 9).

Fig. 9

Knife cutting angle more than 86 °

Access to the knife from the feeding side must be prevented. This may be achieved, for example, by means of a pressing device (hold-down) or other kinds of guards, whereby the gap between the table and the lower edge of the hold-down or guard has to be determined in compliance with the safety distance to the cutting plane as defined in EN ISO 13857.

In the case of foot-operated or automatic pressing (the hold-down is mechanically connected with the downward movement of the knife), the stroke of the pressing device must be limited to 8 mm unless access to the pinching point is prevented by design measures.

The knife edge must be covered in its lowest position (Fig. 10).

Fig. 10

Manual guillotine trimmer, cardboard shear cutter: knife in lowest position

The front paper stop or paper tray must be secured against accidental dropping.

Stack paper cutter

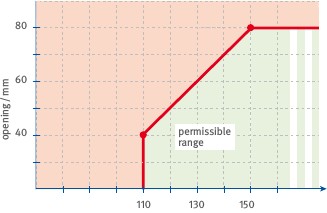

On the cutting side, a hinged tunnel-type guard is required. It must have a length of at least 110 mm, just like the table. An opening may only be present at the front. Admissible opening widths depending on the tunnel length are specified in figure 12. If possible, the hinged tunnel-type guard should prevent direct access to the blade's danger zone.

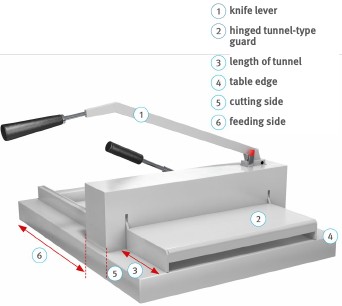

Fig 11

Knife protection on the cutting side

If the tunnel-type guard is open, the downward movement of the knife must be prevented. Lifting of the blade cover must be allowed only if the knife is in the top position.

Downward movement of the knife must be possible only if the cover is in guarding position.

Fig. 12

Opening width in relation to the tunnel length

Access to the knife from the top must be prevented.

A tunnel-type guard of at least 110 mm lengt is required on the feeding side so that the knife cannot be reached. The possible opening widths are shown in figure 12. In case the guard is of the hinged type, the requirements specified left at paragraph "stack paper cutter" also apply.

In the top position of the knife, the knife edge must always be covered by the hold-down.

The lever holding the knife and the hold-down must be safely secured in the top position.

For knife changing, adequate supporting elements with blade covers must be provided in order to make knife changing safe.

Knife changing procedures must be described in detail in the operating instructions.

Rotary cutters

The rotary knife must be secured against contact except for that part used in the cutting operation.

Changing the cutter head (rotary knife) must be easy.

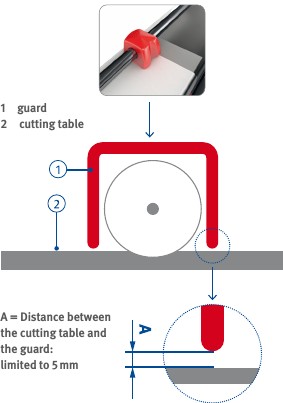

The distance between the cutting table and the guard covering the rotary knife must not exceed 5 mm on the inlet and outlet side (Fig. 13, A).

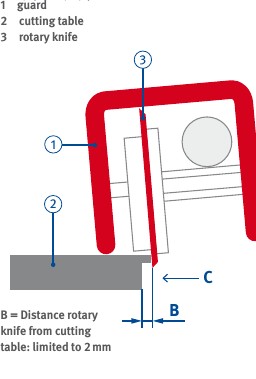

Fig. 13

Cover guarding the rotary knife

The distance between the rotary knife and the cutting table should not exceed 2 mm (Fig. 14, B). A minimum distance is not required for blunt rotary knives (cutting angle greater than 86 °, see Fig. 9).

Fig. 14

Cutter Head

In its lowest position, the knife edge of the rotary knife must be guarded by the cutting table, unless blunt rotary knives (Fig. 14, C) are used.

Paper dispensers

The knife edge must fit closely to the paper or foil roll so that inadvertent contact is not possible.

The paper or foil roll must be secured against falling out of its support.

On movable dispensers, at least 2 castors must be lockable.

Fig. 15

Paper dispenser

Operating instructions

The operating instructions must precisely describe the intended handling.

If assembly is necessary for safe handling of the appliance, this must be described in the operating instructions.

For rotary cutters and manual guillotine trimmers with blunt knives, the operating instructions may be given on the packaging.

If guarding elements are not mounted at the time of sale, the operating instructions must include detailed assembly instructions and a warning that the machine must not be operated without the guarding system.

Where knife holders are secured by force-fit friction, the operating instruction must indicate that the

efficiency of friction elements must be checked regularly. A detailed description of the method of readjustment is also required.