Abschnitt 3.1 - 3.1 Evaluation phases

A Risk assessment must be carried out by the employer within the context of an evaluation of working conditions in accordance with Article 5 of the German Occupational Safety and Health Act (ArbSchG) [2] and DGUV Regulation 1 "Principles of Prevention" [3].

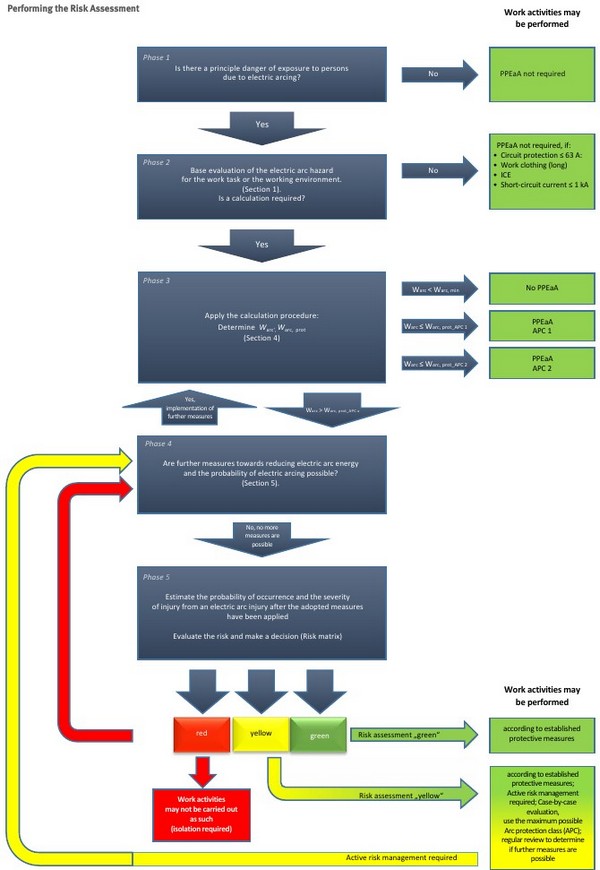

A sensible approach with regard to the thermal effects of electric fault arcing is depicted in the flow diagram in Fig. 3-1.

The individual phases of the Risk assessment are:

Phase 1: Is there a principle danger to persons from exposure due to electric fault arcing?

An estimation is made for the specific work situation as to whether electric fault arcing should be anticipated. In this process and on the basis of one's own company, the structure, condition and age of the installation, the intended work activity, as well as the qualifications and experience of the executing personnel, for example, should be considered.

If the results show that there is no danger to persons from exposure to electric fault arcing, then PPEaA is not required.

Phase 2: Initial evaluation of the electric arc energy associated with the scope of activity or workplace.

Is a calculation required?

Although there are work areas and activities where the onset of electric fault arcing cannot be ruled out, there are also areas where the expected amount of electric arc energy is so small that a hazard due to its thermal effects is not expected.

It is therefore set forth in the Scope of Application (Section 1) of this DGUV Information that the use of PPEaA can be dispensed with in the following cases:

When working on measuring, control and regulation equipment with upstream electric circuit protection up to 25 A.

When working on electrical circuitry with rated voltages up to 400 V with upstream protection up to 63 A, insofar as an outfit of customary work clothing comprised of long-sleeved outer clothing and long pants is worn.

When working on electrical circuitry with rated voltages up to 400 V AC and a short-circuit current < 1 kA. (This type of electric arc will burn unstably and extinguish immediately.)

If one of the applications mentioned above applies, then neither PPEaA nor a calculation is required.

Phase 3: Apply the calculation methodology:

determine the electric arc energy Warc, and level of PPEaA protection Warc, prot!

The calculation process for the selection of PPEaA, as described in Section 4, is applied during this phase.

Four different results are possible:

Warc < Warc, min

The expected electric arc energy is less than the minimum value of 50 kJ, beyond which skin burns due to direct exposure cannot be ruled out (Warc, min ). This means that PPEaA is not required.

Warc ≤ Warc, prot_APC 1

The expected electric arc energy is less than the PPEaA protection level Warc, prot with a class APC 1. PPEaA in the Arc protection classes APC 1 or APC 2 provides sufficient protection against the thermal effects of an electric fault arc.

Warc ≤ Warc, prot_APC 2

The expected electric arc energy is less than the PPEaA protection level Warc, prot with a class APC 2. PPEaA in the Arc protection class APC 2 provides sufficient protection against the thermal effects of an electric fault arc.

Warc > Warc, prot_APC x

The expected electric arc energy is greater than the PPEaA protection level Warc, prot_APC x (Arc protection classes APC 1 or APC 2) provided by the PPEaA available. In this case, proceed with Phase 4.

Phase 4: Implement further measures towards reducing electric arc energy and the probability of injury due to electric fault arcing.

Further measures towards reducing electric arc energy and the probability of injury due to electric fault arcing must be adopted and implemented.

Fig. 3-1

Risk assessment flow diagram

Instructions for possible measures are described in Section 5, "Instructions for practical application".

The Risk assessment must be carried out again subsequent to Phase 3. If no further measures towards reducing electric arc energy and the probability of injury due to electric fault arcing are possible, then proceed with Phase 5.

Phase 5: Estimate the probability of occurrence and the severity of injury due to electric fault arcing after the adopted measures have been implemented; evaluate the residual risk and make a decision (Risk matrix)

If the protection level Warc, prot afforded by the PPEaA available is less than the arc energy Warc determined in Phase 3, then the Risk assessment can be expanded to consider the probability of personal injury. An estimation of risk can be undertaken in so doing.

| The starting point for estimating the risk in Phase 4 should always be the precise calculation of the expected electric arc energy in Phase 3, not a worst-case estimation on the basis of reference or extreme values, which is also an option there. |

|---|

The residual risk of an injury due to the effects of electric arcing must be evaluated after the measures aimed at preventing an electric arc occurrence and its effects have been implemented.

This residual risk results from the combination of

the anticipated severity of injury and the

probability of injury, while accounting for the respective adopted measures.

Assistance in determining the anticipated severity of injury and the probability of this injury occurring can be found in Annex 4 of this DGUV Information.

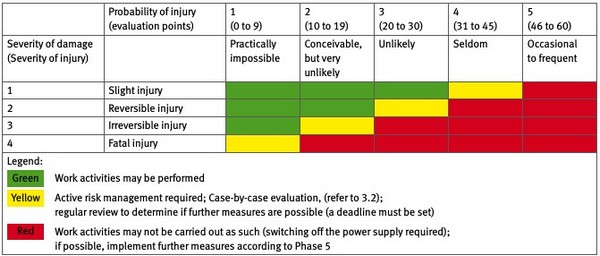

Using the Risk matrix

When using the risk matrix (Fig. 3-2), probability of injury and the severity of a possible injury due to the effects of electric fault arcing must be applied - while accounting for the respective adopted measures.

According to the Risk assessment flow diagram (Fig. 3-1), a classification in the "Red" category calls for the adoption and evaluation of further measures (Phase 4), or the work must be performed only with all relevant system components in an isolated state. Adjacent live parts of the installation must be covered or gated.

Fig. 3-2

Risk matrix: Risk of injury after implementing the adopted measures