Abschnitt 6.3 - 6.3 External cargo and installation flights

The helicopter must have available a weighing system to determine the load.

| Reasonable set-up of complex load bearing equipment for external loads (additional equipment) | |

|---|---|

| Helicopter with primary cargo hook |  |

| Shock absorber (attenuating element) Polyamide rope, double or 4-fold, loose or jacketed, operating elongation approx. 15% length 1 to 2 m, end fitting for primary cargo hooks according to manufacturers' specifications |  |

| Lifting rope systems of sufficient length Low-torque steel rope (e.g. crane lifting rope) or synthetic fibre ropes with low elongation, cross section circular, as small as possible, weight in relation to cargo hook as low as possible, operating elongation as low as possible |  |

| Swivels Torsion tensions cannot be absorbed by cables |  |

| Cargo hooks with sufficient dimensions Manual or electrical end fitting for primary cargo hooks according to manufacturer's specifications |  |

| Slings |  |

The overall length of the load rope including swivel and cargo hook should be significantly below or above 1.5 times the rotor diameter.

Flight operation

The helicopter pilot must ensure the safe lifting or setting down of the external load under all possible flight conditions.

Measures for safe load lifting

The helicopter is centred over the centre of gravity of the external load and the Load Lifting Devices tightened by slow vertical ascent. Only then is the load lifted. It is safeguarded by the Marshallers that no further persons are in the hazard area. Foreign bodies, loose parts or covers on or at the load are to be removed beforehand.

Measures for safe offloading

The external load is positioned over the storage or installation area and slowly set down according to the work task. With this guiding lines are to be handled freely. They may not be entangled or tied. Oscillating loads are to be avoided, as manual damping is not possible in most cases.

It is ensured by the Marshallers that only those persons that are necessary to the immediate continuation of work are in the danger zone. The fine positioning, the setting down or a necessary jacking of the external load is directed or monitored by the Marshaller.

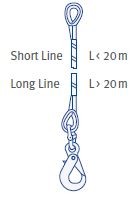

Measures in the case of assignments using Long Line

A flight procedure with the necessary approach or departure height is to be selected, if a Long Line is used. In order to prevent a flying up of the complex Load Lifting Devices in the case of transfer flights with a Long Line, negative vertical accelerations or too high forward speeds are to be avoided. If necessary, additional weights or other aerodynamic components are to be mounted on the lower end.

The helicopter pilot must inform him/herself or be informed of the position of the external load during the whole flight. This can be carried out by

external mirror or bubble on the helicopter,

a Marshaller on board (external load instructor),

a Marshaller on the ground, who is in constant audio connection with the pilot.

The whole flight involves load lifting, transport and offloading down. If necessary, different measures must be combined with each other.

The Marshaller has to ensure that external loads are safely attached and cannot come loose unintentionally. Before lifting or setting down the load, the electrostatic charge is to be discharged from the helicopter cell, the load or the complex Load Lifting Devices.

Suitable measures here are, for example:

contact of the Load Lifting Devices with the ground before lifting the load

ground contact of the helicopter before lifting the load

grabbing hold of the load or the Load Lifting Devices using a sufficiently earthed arrestor hook, in order to discharge electrostatic charges properly

Marshallers on the ground wear high-visibility work clothes, which clearly stand out from the colouring of the other insured individuals, appropriate for seasonal weather and the assignment area, e.g. high visibility clothing according to DIN EN ISO 20471.

The employer must provide a sufficient number of Marshallers to shorten the assembly and dismantling time and therefore the "confined area" situation of the helicopter. This must be oriented on the type and extent of the work task.

The safety distance to live overhead power lines must be at least 5 m.

A suitable emergency landing place for the helicopter and a jettisoning area for the external load must be determined before starting work. This is to be fenced off for the period of work and secured against access by third parties.

Further measures to minimise hazards can result from the risk assessment.