Abschnitt 6 - 6 Storage of magnesium chips and magnesium residues

The fire load caused by magnesium chips and other magnesium residues (e. g. dross, sludge, dust etc ...) in the working area must be kept low. A regular removal into storage areas which are outside the production area must be ensured.

In general, magnesium chips and residues come under the Ordinance on Hazardous Substances and must therefore be separated from other residual materials and fire loads.

The storage area and the containers used have to be properly marked in accordance with the Ordinance on Hazardous Substances.

Care must be taken to ensure that the moist chips which are conveyed out of the machine are fed directly into a collection container with limited volume or, in case of a high quantity, are directly conveyed to briquetting. It is recommended not to exceed a residual moisture content of the briquettes of 3 %.

When storing magnesium sludge in barrels or tippers, it has to be ensured that they do not overheat (hazard of exothermic reaction) and are not exposed to direct sunlight.

One possibility is to completely cover the contents of the barrels with water. The resulting reaction heat can cause a relatively strong evaporation. The barrels must be regularly checked and refilled with water, if necessary. The loss of water can lead to "boiling over".

Figure 36

Briquetting system

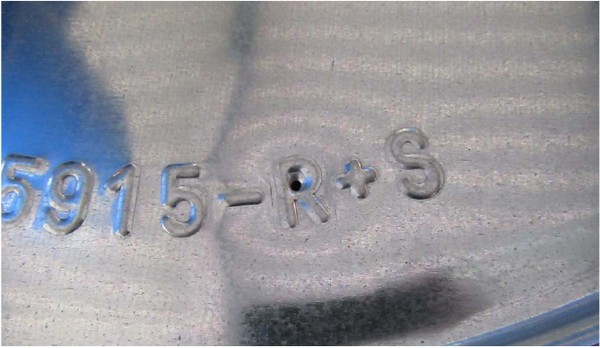

Figure 37

Barrels with vents

Requirements for storage areas

Enough quantities of suitable extinguishing agent must also be available in storage areas.

A good ventilation must be ensured.

The storage areas have to be kept free from ignition sources (smoking ban, no sparking work, no battery charging points, etc.).

Dry and slightly oil-containing magnesium chips and dusts (e.g minimum quantity lubrication) should be stored and transported in tightly sealed, non-combustible containers, for example steel barrels.

Dry storage protected from weather effects is required, as the ingress of moisture can lead to the formation of hydrogen or self-ignition.

For the storage and transport of moist magnesium chips and dusts which are wetted or soiled with water-mixed metalworking fluid, closed containers have to be provided, which are designed in such a way that released hydrogen can escape safely, for example with a vent in the cover area.

For the storage and transport of magnesium sludge, uncovered containers must be available from which released hydrogen can safely escape.

The containers must consist of suitable materials and marked in accordance with the Ordinance on Hazardous Substances.

Abrasive sludge, filter material covered with magnesium particles and dross should be stored outdoors, outside the production facility. The storage area must be roofed and protected against rain and lightning.

Magnesium should be stored

protected from weather effects and strong sunlight,

at a sufficient distance from buildings and

in non-combustible containers with lid/cover.

Storage areas must be

kept free from other combustible materials (wood, cardboard, etc ...),

protected against unauthorized access and

adequately marked.