Abschnitt 5.3 - 3. Electrical work

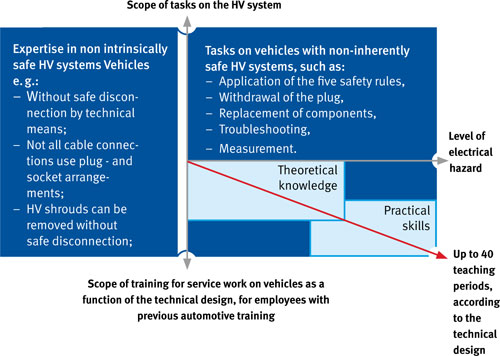

Work on the conventional vehicle electrical system up to 30 V AC/60 V DC must be distinguished from the work on HV components. The scope of training depends in part upon the level of the electrical hazard (implementation of intrinsic HV safety on the vehicle) and upon the employee's prior knowledge.

In the skilled vocations in the automotive sector, basic electrical knowledge is taught in the theoretical component and work involving the conventional vehicle electrical system up to 30 V AC/60 V DC in the practical component, according to the relevant curricula. In addition, the measurement of electrical values and work on electrical components and systems is taught in a practical way in both industry-wide and company-level training. This has been the case in Germany for trades including those of car mechanic, auto-electrician and automotive mechatronic technician since 1973, and for those of car-body repairer, body and vehicle construction mechanic since 2002. Persons who have successfully qualified in one of these skilled vocations since the dates stated or have completed a comparable vocational course of training, for example a degree in automotive engineering, or who are able to demonstrate appropriate further specialist training as an automotive service technician or master car mechanic, already possess the necessary basic electrical knowledge. Based upon this level of knowledge and experience, these employees receive further training in work on vehicles with HV systems. Persons without prior electrical knowledge must in addition be taught basic electrical principles.

In order for the prospective participant's current level of knowledge and experience to be quantified prior to the training measure, the necessary electrical knowledge must be determined by a pilot test. This provides both the participant and the employer with the certainty that the prior knowledge is sufficient for successful completion of the training measure.

The theoretical and practical training must be concluded with demonstration of the skills and knowledge that have been acquired. The demonstration of the acquired skills and knowledge must be documented.

3.1 Service workshops for vehicles with intrinsically safe HV systems, particularly passenger cars

The training described below assumes that work is being performed on vehicles with intrinsically safe HV systems. Should the intrinsically safe nature of the HV system not be assured, training as described in Chapter 3.2 for service work on commercial vehicles is required.

The flow chart in Annex 7 provides support in determining the necessary scope of training.

The topics covered by training listed serve as an example only and must be adapted to the specific requirements of the tasks.

- a)

Prior training: persons without prior electrical knowledge but with technical training

Topics covered by training:

Basic electrical knowledge,

Electrical hazards and first aid,

Measures for protection against electric shock and against fault arcs,

Organization of safety and health for electrical work,

Specialist and man-management responsibility,

Employee qualifications in the area of electrical engineering,

Use of HV systems in vehicles.

A specification of the topics covered by training can be found in Annex 4.

The theoretical component of the training must encompass at least 72 teaching periods.

- b)

Prior training: persons with prior electrical knowledge in the automotive sector (e. g. auto-electricians, automotive mechatronics technicians, car mechanics)

Topics covered by theoretical training component:

Specialist and man-management responsibility,

Electrical hazards and first aid,

Measures for protection against electric shock and against fault arcs,

Electrical work in accordance with the BGV/GUV-V A3 accident prevention regulation and with DIN VDE 0105-100,

HV concept and automotive technology, safety requirements in accordance with Federal ECE Rule 100.

A specification of the topics covered by training can be found in Annex 8.

The theoretical training component must encompass at least 8 teaching periods, plus examination.

- c)

Skilled electrical persons, e. g. industrial electronics specialists, electrical fitters, electrical engineers

Skilled electrical persons such as industrial electronics experts or electrical fitters possess the necessary basic electrical knowledge and require additional practical knowledge of work with high-voltage components.

Required additional practical component

Following the theoretical training, additional practical training components are required, according to the nature and scale of the HV system concerned (e. g. hybrid drive, fuel cell, electric vehicle). The actual scope must be based upon the manufacturer's specifications. The practical knowledge can be communicated by a number of different teaching methods in consideration of the work to be carried out on the HV system. The practical component can also be carried out by the bodies responsible for the theory component, provided the relevant HV systems or comparable systems are available for performance of the practical tasks.

The theoretical knowledge acquired must be applied in the practical.

A duration of 4 to 8 teaching periods is required for the hybrid technology currently on the market.

The employer is responsible for assuring performance of the practical component.

Successful completion of training equips the employees to work independently and safely on vehicles with intrinsically safe HV systems. This work includes application of the five safety rules, replacement of HV components such as air-conditioning components and oil pumps in the non-live state, and troubleshooting on shockproof HV components. The employees must be capable of evaluating the work, identifying possible hazards, and selecting and taking the protective measures required for the HV system.

3.2 Service workshops for vehicles without intrinsically safe HV systems, particularly commercial vehicles

Batteries, EDLCs (electrochemical double layer capacitors) and fuel cells with voltages of up to 1.000 V DC are used as electrical energy storage devices in commercial vehicles (and elsewhere). The HV systems of commercial vehicles are not generally entirely intrinsically safe. (Where the intrinsic safety of the HV system is assured, training as described in Chapter 3.1 for service work on passenger cars is sufficient). Successful completion of training equips the employees to work independently and safely on vehicles with non-intrinsically safe HV systems. This work includes application of the five safety rules and replacement of HV components such as drive motors and energy storage devices in the non-live state. It also includes troubleshooting on HV components which may not necessarily be shockproof by means of shockproof test adapters. The employees thus qualified must be able to evaluate the work with which they are tasked, recognize possible hazards, and implement the protective measures necessary for the HV system.

The flow chart in Annex 9 provides support in determining the necessary scope of training.

The topics covered by training listed serve as an example only and must be adapted to the specific requirements of the tasks.

- a)

Prior training: persons without prior electrical knowledge but with technical training

Topics covered by theoretical training component:

Basic electrical knowledge,

Electrical hazards and first aid,

Measures for protection against electric shock and against fault arcs,

Organization of safety and health for electrical work,

Specialist and man-management responsibility,

Employee qualifications in the area of electrical engineering,

Use of HV systems in vehicles.

The topics covered by training must be specified with reference to Annex 4.

The theoretical component of the training must encompass at least 84 teaching periods.

Scope of the practical training component

Besides the theory, the practical component is important, particularly during the introduction of new technology and working procedures. For example, a comprehensive practical component must be included in further training for employees when vehicles with hybrid drive are used for the first time. Should the employees already satisfy the electrical qualification for comparable technology, e. g. EDLCs and batteries, it is sufficient for them to be made familiar in a practical manner with the technical differences and their influence upon the working procedures. The actual scope of the training should be defined in consultation with the vehicle manufacturer. The practical component can also be carried out by the bodies responsible for the theory component, provided the relevant HV systems or comparable systems are available for performance of the practical tasks.

The theoretical knowledge acquired must be applied in the practical.

Owing to the diversity of high-voltage technology and of its implementation by different manufacturers, the training should comprise 12 to 16 teaching periods.

Should the participants already be qualified as defined in Chapter 3.1a), the existing qualification must be supplemented by the teaching in particular of subjects such as the absence of protection against electric shock and fault arcs, protective measures, tests and measurements. The supplementary training must encompass at least 10 to 12 teaching periods for the theory component and 8 to 12 teaching periods for the practical component.

- b)

Prior training: persons with prior electrical knowledge in the automotive sector (e. g. auto-electricians, automotive mechatronics technicians, car mechanics)

Topics covered by theoretical training component:

Specialist and man-management responsibility,

Electrical hazards and first aid,

Measures for protection against electric shock and against fault arcs,

Electrical work in accordance with the BGV/GUV-V A3 accident prevention regulation and with DIN VDE 0105-100,

HV concept and automotive technology, safety requirements in accordance with Federal ECE Rule 100.

The topics covered by training must be specified with reference to Annex 5.

The theoretical training component must encompass at least 24 teaching periods and be geared in its duration to the degree of intrinsic safety of the HV system.

Scope of the practical training component

Besides the theory, the practical component is important, particularly during the introduction of new technology and working procedures. For example, a comprehensive practical component must be included in further training for employees when vehicles with hybrid drive are used for the first time. Should the employees already satisfy the electrical qualification for comparable technology, e. g. EDLCs and batteries, it is sufficient for them to be made familiar in a practical manner with the technical differences and their influence upon the working procedures. The actual scope of the training should be defined in consultation with the vehicle manufacturer. The practical component can also be carried out by the bodies responsible for the theory component, provided the relevant HV systems or comparable systems are available for performance of the practical tasks.

The theoretical knowledge acquired must be applied in the practical component.

Owing to the diversity of high-voltage technology and of its implementation by different manufacturers, the training should comprise 12 to 16 teaching periods.

Should the participants already be qualified as defined in Chapter 3.1b), the existing qualification must be supplemented by the teaching in particular of subjects such as the absence of protection against electric shock and fault arcs, protective measures, tests and measurements. The supplementary training must encompass at least 10 to 12 teaching periods for the theory component and 8 to 12 teaching periods for the practical component.

- c)

Skilled electrical persons, e. g. industrial electronics specialists, electrical fitters, electrical engineers

Skilled electrical persons possess the necessary basic electrical knowledge. They also possess practical knowledge of work with the high-voltage components.

Owing to the diversity of high-voltage technology and of its implementation by different manufacturers, the training should comprise 12 to 16 teaching.

Should the participants already be qualified as defined in Chapter 3.1c), supplementary practical training lasting for 8 to 12 teaching periods is required which particularly addresses the hazards presented by non-inherently safe HV systems.

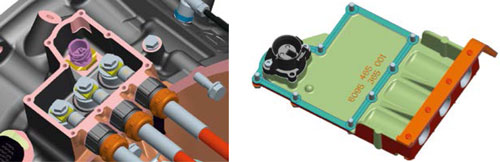

Example of safe disconnection by technical means for the removal of shrouds by means of pilot contact

3.3 Work on live energy storage devices and at test stations

Work on vehicles with HV components must as a rule be performed in the non-live state with observance of the five safety rules. Should work be required in which live parts may not necessarily be safeguarded against contact, for example during troubleshooting or work on energy storage devices or at electrical test stations, the employees must receive additional training. A condition in all cases is training of those concerned as described in Chapter 3.2 for work on vehicles with non-intrinsically safe HV systems; demonstration of satisfactory health, particularly in the form of an occupational medical examination in accordance with DGUV Principle G 25 governing driving, control and monitoring tasks; a minimum age of 18 years; and training in first aid (including cardiopulmonary resuscitation).

Work on the live parts of energy storage devices is required for example when the design of these devices prevents them from being replaced complete and necessitates repair in situ.

The manufacturer's provisions and the requirements of DIN EN 50191 (VDE 0104) and of the BGI 891 informative document concerning test stations must be observed during the testing of HV components. The employees must have experience in working with the components to be tested.

Essential topics covered by training:

Safe working procedures,

Competence of the employees,

Organization of the work,

Tools and protective, testing and other equipment to be used,

Safeguarding of the working areas,

Marking of vehicles on which live parts are exposed,

Test equipment,

Specific non-electrical hazards, such as chemical hazards, risk of fire and explosion,

Practical exercises.

The training of experts in accordance with 3.2 b) and 3.2 c) must last at least 8 teaching periods. Depending upon the complexity of the technology used and the work to be carried out, additional practical tuition may be required, for example an additional 4 teaching periods for cell changing on HV batteries.

Owing to the differences between suitable existing qualifications, the scope of training for experts to Chapter 3.2 a) must be determined on a case-by-case basis with reference to Section IV Chapter 1.4.

Example of safeguarding of the working area during testing work