Abschnitt 4.3 - Exceptional features in the design of conveyors using laser scanners

If laser scanners are used as safety devices during the movement of the transfer car the front covers at the conveyors may not reach to the floor.

If laser scanners are used as safety devices during the movement of the transfer car the conveyors have to be equipped continuously with front covers. However this is only possible for the upper part of the conveyor. The lower part has to be kept free from covering to enable a scanning underneath of the conveyor. The height of the uncovered part depends on the height of the laser scanner protective field.

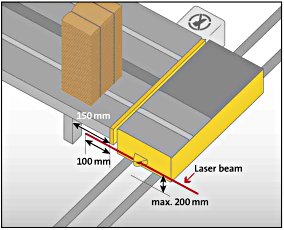

In order to guarantee a safe detection also of lying persons the laser scanner has to be installed in that way that a test object for checking the detection capability of the laser scanners will reliably be detected. The test object is a cylindrical tube at a diameter of 200 mm (→ acc. to DIN EN 1525). The adjustment of the protective field height is done by the manufacturer.

It is recommended to install the feet of the conveyors (as shown on picture 2) at a distance of at least 150 mm from the conveyor edge to enable a trouble-free scanning of the area underneath the conveyor.

PICTURE 2: Covering of front edge and scanning underneath of conveyor

Only in this way it is possible to guarantee a scanning range of at least 100 mm from the front edge of the conveyor. The measurement of 100 mm is calculated on the basis of the technical parameters for the safe detection of the edge blur plus a safety margin.