Abschnitt 6.4 - 6.4 Working on earth-moving equipment and other automotive machines

6.4.1 General

The individual parts of the work equipment and the chassis of earth-moving machines, as well as other automobile machines may be characterized by high dead loads. Along with present oil pressure, accumulators are used frequently posing a particular risk potential (see section 4.7).

Earth moving machines frequently are repaired, serviced and maintained in rough terrain or on construction sites.

Sudden position changes of the machine or its parts, as well as the risk of falling down when being on higher parts of machines while implementing maintenance work cause particular hazards (see section 6.4.3).

6.4.2 Securing machines and machine parts against movement

Before starting any maintenance work, the machine has to be driven onto level territory with firm ground and has to be secured against rolling. The work equipment is to be lowered.

If the maintenance work cannot be carried out on level territory, if work has to be done on the braking system, or if the machine has to be jacked up on one side, an additional safeguarding measure by means of stop-blocks is required.

If machines are lifted for maintenance work, the machines have to be supported by means of bearing frames or with cross stacks consisting of boards or square timbers before starting any work. Work on lifted machines or devices that are only held by the hydraulic pressure of the machine or the vehicle are inadmissible.

By lifting a machine with articulated steering on one side or due to a loss of pressure in the hydraulic system, the steering system could be activated suddenly. In this, the machine may loose its stability and persons standing near the machine could be wedged. If works have to be implemented in the area of the articulated steering system or if machines having an articulated steering system have to be jacked up, the mechanical articulated steering lock (positive locking fixing device) has to be engaged first.

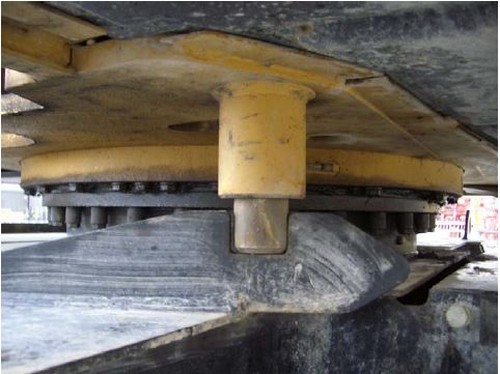

When working on hydraulic excavators, the superstructure has to be secured against swiveling before starting any maintenance work (see figure 40).

Furthermore, it has to be observed that hydraulic excavators and loaders are equipped with counterweights. If heavy parts have to be disassembled, the machine could tilt on the basis of the changed center of gravity.

Fig. 40

Swivel lock on a hydraulic excavator in locked position

Work equipment has to be secured against moving by placing it on the ground, supporting it, or equivalent measures before starting any work. If work has to be conducted below the lifted work equipment, the latter has to be secured against lowering by means of the designed positive fitting supporting devices (see figure 41).

If there are no such safeguarding measures, the corresponding part has to be supported by means of bearing frames having sufficient load-carrying capacity. Stacking construction materials is not suitable to this end as these materials could lose their stability in case of impulsive stress when mounting the part.

Fig. 41

Supporting device in place on an earth-moving machine

6.4.3 High-level places of work

It has to be possible to reach platforms for maintenance and repair work in a safe manner. If there is the risk of falling down, appropriate safeguarding equipment has to be used. Hydraulic components must not be used as climbing aids or attachment point for safeguarding equipment against falling.

Parts of the machine must only be used as place of work or access if the manufacturer has designed them to this end and if they are stable and skid-proof.

If mounting work on site is conducted with the help of other work machines or industrial trucks, they have to be approved for these purposes and have to be equipped with an admissible device for accommodating persons, e. g. work platform; see DGUV Information 201-029 "Handlungsanleitung für Auswahl und Betrieb von Arbeitsplattformen an Hydraulikbaggern und Ladern" (Handling instructions for selecting and operating work platforms on hydraulic excavators and loaders). Works must not be carried out from lifted work equipment, e. g. shovel or fork/pallet.

6.4.4 Depressurizing

Before starting to work, the pressure in the hydraulic system has to be reduced. This has to be done in accordance with the manufacturer’s specifications.

Normally, accumulators are used in the steering, braking or hydraulic pilot control systems of machines, as well as in the work hydraulic circuits of loaders/loading machines as vibration dampening system. They have to be depressurized on the fluid side before starting any work.

Note:

If the accumulator of the hydraulic pilot control system has been depressurized already, the work equipment may only be lowered by means of a manual emergency lowering device by hand, e. g. via load holding valve on the boom of an hydraulic excavator.

| Note |

|---|---|

| Before re-commissioning, load holding valves have to be re-adjusted in accordance with the manufacturer’s specifications! | |

The hydraulic tank on work machines can be under overpressure due to operating conditions. Before starting any work on the hydraulic system the tank has to be depressurized.

6.4.5 Disassembling parts

It may be required to use lifting gear in order to carry out mounting work on hydraulic components. On construction sites this work is often conducted with the help of other earth-moving machines. It has to be observed that the manufacturers designed and equipped these machines for lifting gear operation. The notices in the operating instructions have to be observed.

During the mounting work, chain hoists may be of help allowing for positioning the parts precisely.

Hydraulic cylinders have to be lifted by means of suitable lifting accessories, e. g. attached with lifting straps or round slings in two-stringed design. Extending of the piston rod during the lifting procedure can be prevented by closing the connections using blind plugs after having disconnected the lines.