Abschnitt 4.2 - 4.2 Pipelines

Pressurized fittings of pipelines must not be opened.

If pipelines are replaced, standardized seamless cold-drawn precision steel pipes have to be used. When selecting these pipes, the requirements of the machine manufacturer with regard to material characteristics, wall thickness, cross sections and the admissible operating pressures have to be observed (see parts list).

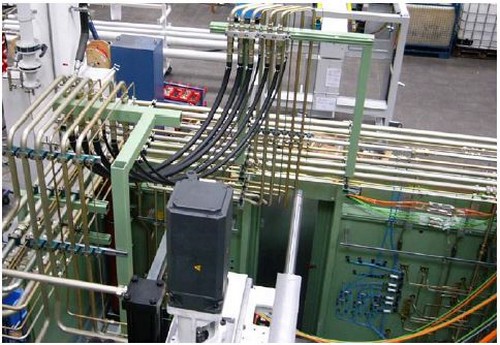

Fig. 9

Central hydraulic system at commissioning

Some connection element manufacturers rate the nominal pressures in deviation from the standards. Thus, parts having the same dimensions can be characterized by substantial differences regarding the nominal pressures. Similar thread sizes of different systems (metric/imperial) must not be confused!

| Note |

|---|---|

| When procuring spare parts attention must be paid to the fact that parts having the same dimensions can be characterized by different nominal pressures and thread types! | |

If pipelines have to be re-routed within the framework of maintenance work, they have to be attached by pipe clamps in an adequate manner.

The following distances are recommended:

| External pipe diameter | Recommended spacing 1) between two pipe clamps (according to DIN EN ISO 4413) | ||

|---|---|---|---|

| From a pipe connection | Between two supports in the case of a straight pipe | From a pipe bend | |

| up to 10 mm | 0.05 m | 0.6 m | 0.1 m |

| over 10 mm to 25 mm | 0.10 m | 0.9 m | 0.2 m |

| over 25 mm to 50 mm | 0.15 m | 1.2 m | 0.3 m |

| over 50 mm | 0.20 m | 1.5 m | 0.4 m |

Fig. 10

Proper attachment of pipelines with pipe supports

In doing so, it has to be observed that the pipeline is not damaged, e. g. attaching it by welding is inadmissible. No other parts must be attached to pipelines.

The pipe elbows have to be bent taking into account the details regarding the bending radii and the use of appropriate devices ( e. g. pipe bending machine). The pipes must not be buckled when they are bent. Pipes subjected to heat treatment have to be cleansed and descaled.

Before being installed, pipeline components always must be deburred, cleansed, and installed in accordance with the provisions of the fitting suppliers.

Fig. 11

Pipeline routing in a large machine

If line connections can be confused, they have to be marked clearly and permanently by the maintenance technician before being disconnected.

During assembly, the newly installed connections have to be tightened in accordance with the manufacturer’s instructions, e. g. using the torque wrench or according to specified angle of twist, in order to avoid shear forces and tensions.

Pipelines and fittings have to be checked for leaks up to maximum operating pressure before they can be approved.

If pipeline fittings show leakages, these have to be remedied. For this, depressurized condition has to be established first. Afterwards, the following measures can be implemented:

Checking the tightening torques of fittings,

checking the tightening torques of flange connections,

replacing the seals.

Reproduced by permission of DIN Deutsches Institut für Normung e. V. For applying the DIN-standard, the recent issue which can be obtained from Beuth Verlag GmbH, Burggrafenstraße 6, 10787 Berlin, Germany is decisive.]