Abschnitt 6.1 - 6 Assignment-specific measures

6.1 Refueling helicopters

This is a summary of the most important safety requirements for the refueling of helicopters from non-stationary refueling systems.

6.1.1 Aircraft fuel

Common types of aircraft fuel are JET A-1 (kerosene) for turbine engines and AVGAS 100 LL (aviation petrol) for piston engines. Both varieties are detrimental to health in case of inhaling concentrated vapour-air-mixtures and flammable or explosive under certain temperature and air circulation conditions. The specification LL (low-leaded) or UL (unleaded), for example, is used for the precise designation of the fuels in the case of AVGAS and the specification JET A-1 or JET-B, for example, in the case of kerosene. In order to be able to judge the fire or explosion hazard quantitatively, key indicators, e.g. the flashpoint, the ignition temperature or the lower and upper explosion limit are determined.

| Types of aircraft fuel | JET A-1 | AVGAS 100 LL |

|---|---|---|

| Flashpoint | above +38°C | below -18°C |

| Hazard class | flammable | extremely flammable |

| UN number | UN 1863 | UN 1203 |

| Class | 3 | 3 |

| Classification code | F1 | F1 |

| Packaging group | III | II |

| Ignition temperature | approx. +220 °C | approx. +220 °C |

| Explosion limits in air | approx. 0.6 to 6.5 Vol.-% | approx. 0.7 to 8.0 Vol.-% |

The safety data sheets of fuels contain further information.

Whether normal commercial vehicle fuel (MOGAS - e.g. "Super Plus 98") may also be used, is stipulated in the flight manual. If no stipulation was made here, the manufacturer of the helicopter must grant an approval.

6.1.2 Mobile refueling stations

General requirements

Different types of refueling can be considered depending on the type of assignment and helicopter class, e.g. refueling from airfield fuel trucks, tankers, demountable tanks, fuel containers or canisters. According to hazardous goods law approved Intermediate Bulk Containers (IBC) are packages for transport and therefore not "mobile filling stations".

The relevant legal regulations for storage apply in the event of an interruption of transport of aircraft fuel of more than 24 hours. In particular, the aircraft fuel must be stored in such a way that leaking fuel can be detected, collected and eliminated.

The length of the refueling hoses is to be selected so that a minimum distance between feed pump and helicopter can be guaranteed according to the table "potentially explosive area during refueling of helicopters". Coupled hoses are to be avoided.

Refueling with the engine running (hot refueling) is possible with JET A-1 (turbine helicopter), if there are special technical or safety reasons for this and appropriate safety measures to protect the insured individuals are taken.

Technical or safety reasons that permit refueling with the engine running exist among others, if:

the wind conditions do not permit restarting the engine or rotor or

several short flight intervals (rotations), during which continuous refueling procedures are necessary due to the operation, would thermally overload the engine by repeated restarting.

Suitable safety measures are, for example:

The refueling personnel is given special instructions.

Reliable communication helicopter pilot/refueling personnel is ensured.

A third person is deployed for cordoning off the danger zone.

The delivery valve is secured against slipping out of the filling neck on the helicopter side.

The delivery valve is not directed against the engine intake duct.

The distance of the rotor area level to the refueling station and to trees or objects of at least 5 m is maintained. The distance to buildings and facilities must be at least 10 m.

The helicopter pilot remains seated during refueling with his/her seatbelt fastened.

Approaching the helicopter is only carried out at the request of the helicopter pilot.

Special attention is to be paid to the rotor disk area and its distance to the ground when approaching the helicopter.

Due to the high explosion hazard, hot refueling is forbidden under all circumstances in the case of engines that are operated with AVGAS.

Danger zones

A safety distance of at least 10 m is to be maintained at all times to protect buildings, facilities or the helicopter from possible fire hazards.

If the formation of an explosive atmosphere cannot be safely excluded during the refueling process, protective measures are to be taken depending on the classification of the potentially explosive areas.

The appearance of explosive atmosphere can be expected especially in the area of openings, from which gas mixtures can escape. As a result of this fact, it is necessary to prepare an explosion protection document according to the Ordinance on industrial safety and health (BetrSichV).

The explosion protection document must mention, in particular,

that the explosion hazards on the refueling place have been identified and subjected to an evaluation,

that appropriate precautions and measures are taken to combat the hazards and achieve the goals of explosion protection,

which areas were divided into zones,

for which areas which minimum regulations apply and according to which criteria working materials are to be selected and

which organisational measures are required.

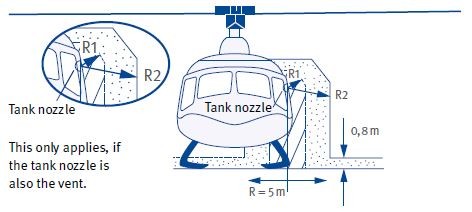

The expansion of the explosive atmosphere depends on the volume flow and the type of fuel (flashpoint) and has the shape of a truncated cone over the discharge opening.

Furthermore, an area (full circle) with a radius of 5 m and a height of 0.8 m is to be adopted as Zone 2.

| Presentation of potentially explosive areas |

|---|

|

The appearance of an explosive atmosphere is occasionally to be expected in the area of Zone 1 during normal operation and in Zone 2 only briefly or not to be expected.

Areas with explosive atmosphere during refueling of helicopters

| Volume flow of the refueling pump [l/minute] | Type of fuel | Danger zone Zone 1 radius R1 [m] | Danger zone Zone 2 radius R2 [m] |

|---|---|---|---|

| <100 | AVGAS 100 LL | 1 | 3 |

| JET A-1 | 0 | 1 | |

| <600 | AVGAS 100 LL | 5 | 8 |

| JET A-1 | 0 | 1 |

Protective measures are to be taken in potentially explosive areas that prevent or restrict the danger of the ignition of dangerous explosive atmosphere or limit the impact of an explosion to an extent that they can be considered harmless. These include, for example:

Zone 2: Ignition sources to be expected during operation (ignition sources that can arise during normal, smooth operation, such as during switching operations on the wiring system or radio devices) are to be avoided.

Zone 1: In addition to the ignition sources stated for Zone 2, ignition sources caused by operational disruptions, which must be expected from experience (malfunctions that are realistically to be expected) are also to be avoided. Operating materials, installations and plant parts, where the appearance of ignition sources can be expected, must have an explosion-proof design and, if necessary, be spark-proof.

Furthermore, a danger zone with a radius of 5 m around the mobile refueling station and the feed pump with the hazard level corresponding to Zone 2 is to be adopted. These danger zones are to be marked with prohibition signs "No open flame; fire, open ignition source and smoking forbidden" and "Access by unauthorised persons forbidden".

Signs that comply with the Technical Rules for work places "Safety and Health Protection Signs" (ASR A1.3) are suitable.

| P003 No open flame; open ignition source and smoking forbidden |

|---|

|

| D-P006 Access for unauthorised persons forbidden |

|---|

|

Fire protection equipment

Suitable fire extinguishers to fight an incipient fire are to be provvided in sufficient number corresponding to at least 18 Extinguishing Agent Units (EAU).

Suitable fire extinguishers are, for example, powder extinguishers with ABC dry powder of type PG 6 (6 EAU) and PG 12 (12 EAU).

Environmental protection equipment

If any mobile tanks used are not double-walled, these are to be placed in adequately dimensioned vats that are made of conductive and non-flammable material. This also applies for barrels and canisters. The entry of rainwater must be prevented, as this reduces the possible collection volume.

In order to avoid soil contamination when decanting and refueling, suitable collecting vessels are to be provided.

If spills, dripping or leakages have occurred, leaked fuel must be absorbed immediately with suitable binding agents and disposed of correctly.

Mobile refueling is to be avoided in water protection areas. Where it is unavoidable, coordination with the regionally competent authority for water protection is urgently recommended.

Refueling process

To guarantee safe fuel applications, a type-compatible, clean fuel that is free of impurities is important. In particular, it must be ensured that no water constituents are contained in the fuel, as fuel is in a position, depending on its temperature, to store water invisibly.

In order to ensure a reliable supply of aviation fuel, a needs-based and punctual delivery is required. It is to be taken into account that a sufficient settling time of the delivered aviation fuel in the storage tank is complied with before the first refueling. In this way, possibly existing condensation and other impurities can settle at the bottom of the container. Samples are to be taken at the tank's low point before first refueling, in order to check whether the fuel is flawless.

Refueling may not be carried out within the sphere of influence of a thunderstorm. Thunderstorm situations, from which risks can arise, are not clearly defined. It is to be assumed that discharges capable of igniting are possible in the case of storm fronts that are at a distance of 5 to 6 km. The thunder is already easily audible at this distance.

The helicopter is to be parked ideally on firm and level ground and secured against rolling away, if necessary. The refueling Marshaller must coordinate with the pilot before starting the refueling process. In particular, all the necessary work steps for refueling are to be coordinated, in order to minimise a reciprocal hazard especially during refueling with the engine running.

Risks due to electrostatic charges exist during every refueling process. In order to reduce these to a minimum, conductive connections (equipotential bonding) between the helicopter and the refueling system or the refueling device must be secured.

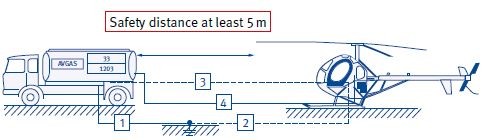

| Refueling with AVGAS 100 LL |

|---|

|

When refueling with AVGAS 100 LL from permanent or mobile stations, the following technical or organisational measures are necessary:

- 1.

connect tank container or vehicle with an earthing point (earth pin)

- 2.

connect helicopter with the earthing point

- 3.

connect the earthing cable of the tank container or vehicle with the helicopter

- 4.

roll out the hose, open the tank, introduce the delivery valve into the tank and refuel

Dismantling at the end of the refueling process is carried out in reverse order.

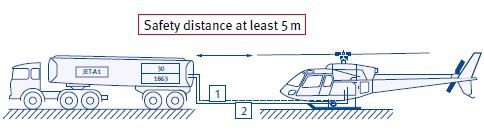

| Refueling with kerosene |

|---|

|

When refueling with kerosene from permanent or mobile stations, the following technical or organisational measures are necessary:

- 1.

produce electrical connection to the equipotential bonding between tank container or vehicle and the helicopter

- 2.

roll out the hose, open the tank, introduce the delivery valve into the tank and refuel.

Dismantling at the end of the refueling process is carried out in reverse order.

The prescribed and marked connection points (bonding points) are to be used to produce a sufficiently conductive connection.

Health protection

The inhaling of vapours is to be avoided. Clothing that has been in contact with fuel is to be changed immediately due to fire hazards and irritations of the skin.

Overfills and spills

In the event of overfills and spills, due to the existing fire and explosion hazard, immediately after the interruption of refueling and the closing of the valves:

the motors, engines and electrical installations are to be switched off

the hazard area is to be secured or cordoned off

The amount of liquid is to be curbed as far as possible and absorbed with oil binding agents.