Abschnitt 2 - 2 Evaluation of hazards caused by fire or explosions

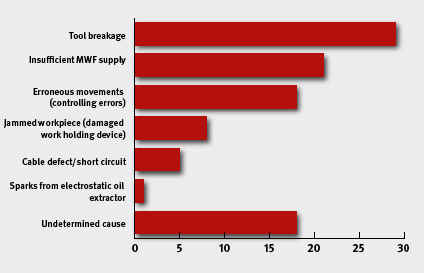

Within the framework of a study carried out by the Verein Deutscher Werkzeugmaschinenfabriken (VDW; Association of German machine tool manufacturers), about 150 fires involving the use of non water-miscible MWFwere investigated in metalworking industries between 1987 and 1994. The causes for these fires are shown in the following Figure.

Figure 5 Causes of machine tool fires [1]

Most incidents were connected with the generation of incandescent chips, high-energy sparks or hot surfaces, which act as ignition sources. As a consequence of technical developments concerning feed and cutting speeds together with the trend towards low-viscosity metalworking fluids used at very high pressures, the fire risk has rather increased.

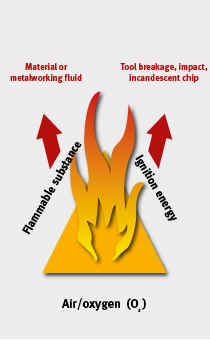

Figure 6 Preconditions for a fire

Figure 7 Reaction around grinding spindle

In the immediate vicinity of machining zone a reactive mixture of MWF and air is formed, which may be ignited by the above mentioned ignition sources. The resulting fire propagates very quickly through the whole interior of the machine tool. The pressure increase accompanying ignition is less important than in the case of an explosion inside a closed system. However, due to the pressure increase inside the machine, flame ejections may occur through gaps, pressed-open enclosure doors, feeding and chip-removal openings and pressure relief openings if no relevant provisions were taken.

Figure 8 Ignition of an MWF/air mixture ...

Figure 9 ... with subsequent fire

In the framework of investigations on the ignitability of spray mists at the PTB Braunschweig [2] the following was determined for ignition sources:

The ignition of MWF spray jets by electric sparks is possible at energies smaller than 10 Joules. Mechanical sparks may also provide a significant ignition hazard in the area around the cutting zone.

Hot surfaces (≥ 800°C) are very effective ignition sources. Hot surfaces are the main ignition sources of fires involving metalworking fluids in machine tools.

Figure 10 Flying sparks

Figure 11 Sparks during drilling

Often, the above mentioned ignition of the MWF/air mixture in the interior of the machine is followed by a subsequent fire. In case of flame ejections from openings and gaps, there is a risk that a machine fire flashes over to the surrounding area.

The risk assessment at the workplace should consider if a machine fire may propagate and flash over to other areas, which strongly depends on the "conditions" surrounding the machine. Liquid films and pools may also catch fire after ignition. The containment of such fires becomes easier as the viscosity and flashpoint of the MWF increases. The most frequent causes of the rapid propagation of a subsequent fire are oil pans filled to the rim and gratings with large surface areas, large-area MWF pools and other flammable materials (paper, cardboard, cleaning rags etc.).

Figure 12 Oil-filled gratings with large surface areas

Figure 13 Machine tool in "oil bath"