Abschnitt 5.5 - Laser scanner

If laser scanners are used special directives apply concerning the covering of the conveyors.

For the use of laser scanners the following should be noted:

- 1.

The installation of the scanners and the evaluation electronic have to fulfil the requirements of → category 3 acc. to EN ISO 13849-1:2006.

- 2.

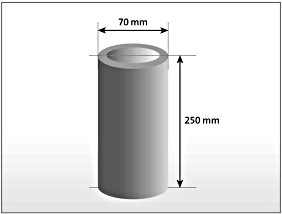

The scanner has to be adjusted in that way that a person standing or lying in the warning and protective field are detected safely. For checking the adjustment for an upright standing person a cylindrical matt black test body is used, the central axis of which runs through the boundary of the protective field (see picture 9).

PICTURE 9: Test body

- 3.

The warning field and the protective field have to be adjusted in that way that persons in the edge zones on the right and on the left alongside the conveyors will be safely detected. Therefore it is necessary to optimally adapt the geometry of the protective field to the existing conveyor dimensions and to allow a scanning underneath of the conveyors by at least 100 mm.

- 4.

Upon infringement of the warning field optical or acoustic warning signals are necessary.

- 5.

Upon infringement of the protective field the transfer car has to be slowed down and brought to standstill as quick as possible. The car has to stop before solid parts of the transfer car hit the person or the obstacle

- 6.

A restart of the transfer car may only be carried out after determination and elimination of the cause for the stop of the transfer car. A manual acknowledgement is required.

5.5.1

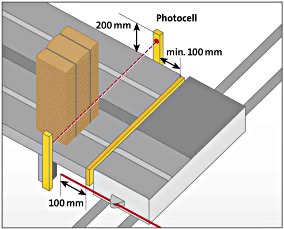

Scanning underneath of the conveyor

The safeguarding of the movement of the transfer car is made by means of a laser scanner that has to scan underneath of the conveyor at a distance of at least 100 mm from the from edge of the conveyor.

PICTURE 10: Additional security by lateral photocells

Additional safety is provided by photocells if they are installed at a height of 200 mm above the conveyor and at a distance of 100 mm from the front edge of the conveyor. The integration of these photocells to the bus system does not need to comply with increased requirements for control systems acc. to EN ISO 13849: 2006.

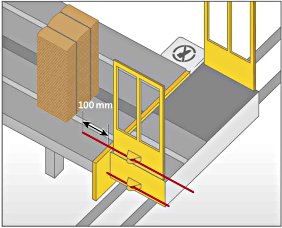

5.5.2

Scanning above the conveyor

If a safeguarding of the movement of the transfer car is secured by a laser scanner, however, a scanning underneath of the conveyor is not possible because the conveyors are completely covered, this area has to be safeguarded by a second laser scanner. This scanner has to scan the area above the conveyor by at least 100 mm.

PICTURE 11: Completely covered conveyors - additional scanner is necessary

Further information

Further information

- →

EN 349 "Safety of machinery/Minimum gaps to avoid crushing of parts of the human body"

- →

§ 17 sec. 2 Workplaces ordinance

- →

EN ISO 13849-1 "Safety of machinery/Safety-related parts of control systems - Part 1: General principles for design"

- →

DIN EN 1525 DIN EN 1525 "Safety of industrial trucks/ Driverless trucks and their systems"